China's original high-strength lightweight scaffolding system leads the world: cracking the "safety-green-cost" impossible trinity in one fell swoop.

China Construction Technology Group took the lead in jointly completing 12 full-scale tests and publishing them in international top journals; HF1350 super thin-walled frame achieves 48m cantilever-free with yield strength ≥1200MPa, steel consumption reduced by 62% and carbon emission reduced by 87%, providing a "high performance, low consumption and high safety" Chinese scheme for low-risk scenarios in the world.

At the key node of accelerating the global construction industry towards carbon neutrality and intrinsic safety, a completely independent innovation technology in China is deeply reshaping the underlying logic of the industry-the HF1350 super thin-walled welded steel pipe scaffold technology system jointly developed by Tianjin University and Fazhe (Zhejiang) New Materials Technology Co., Ltd., led by China Building Technology Group Co., Ltd. and China Building Research Institute Co., Ltd., has successfully built a "central enterprise leading-tackling key problems in universities-private enterprise innovation-local pilot-standard export". With the hard-core indicators of yield strength ≥1200MPa, carbon emission in the whole life cycle reduced by 87%, and comprehensive cost reduced by over 50%, this technology successfully ended the bipolar dilemma of traditional "black-hearted pipe flooding" and "one-size-fits-all abuse", and provided a replicable, scalable and sustainable "China scheme" for low-risk scaffolding application scenarios around the world.

First, face the global common problem: scaffolding is caught in the triple paradox of "safety-green-economy"

As the most widely used temporary structure in the world, scaffolding consumes more than 100 million tons of steel every year. However, the existing mainstream technology paths all have obvious defects:

Traditional Q235 fastener scaffold (accounting for more than 80% of the Asian market): the material strength is low (ReL≈235MPa), and it relies on heavy steel pipes to ensure safety. However, the market is flooded with a large number of non-standard "black-core pipes" with a wall thickness of only 2.6mm (the national standard requires ≥3.6mm), with insufficient bearing capacity, high risk of instability and frequent accidents. Even for compliant products, due to insufficient rigidity, I-beam cantilever is required every 20 meters, which leads to complicated construction, great leakage potential and prolonged construction period.

Buckle-type/aluminum alloy scaffold (mainstream in Europe and America): high safety, but the steel consumption is as high as 45-60 kg/m (only 15-20 kg/m for traditional scaffold), which is "performance redundancy" in low-risk scenes such as faç ade. Its high cost (about twice that of the traditional frame) and high implied carbon emissions run counter to the global trend of "green construction".

"The world needs an intermediate solution that is neither as dangerous as' bean curd residue' nor as extravagant as' body armor'." An international engineering consultant said bluntly.

Second, China broke the game: reconstructing the scaffold technology paradigm with the material revolution

China's team took a new approach, focusing on the material performance jump rather than the simple stacking of structural forms. By developing HF1350 high-strength steel with tensile strength ≥1400MPa and yield strength ≥1200MPa, and cooperating with 1.3mm precision welded pipe process, the weight per meter is only 1.5kg (3.97kg for traditional pipe) and the material saving rate is 62% on the premise of maintaining the outer diameter of 48mm (compatible with existing fasteners).

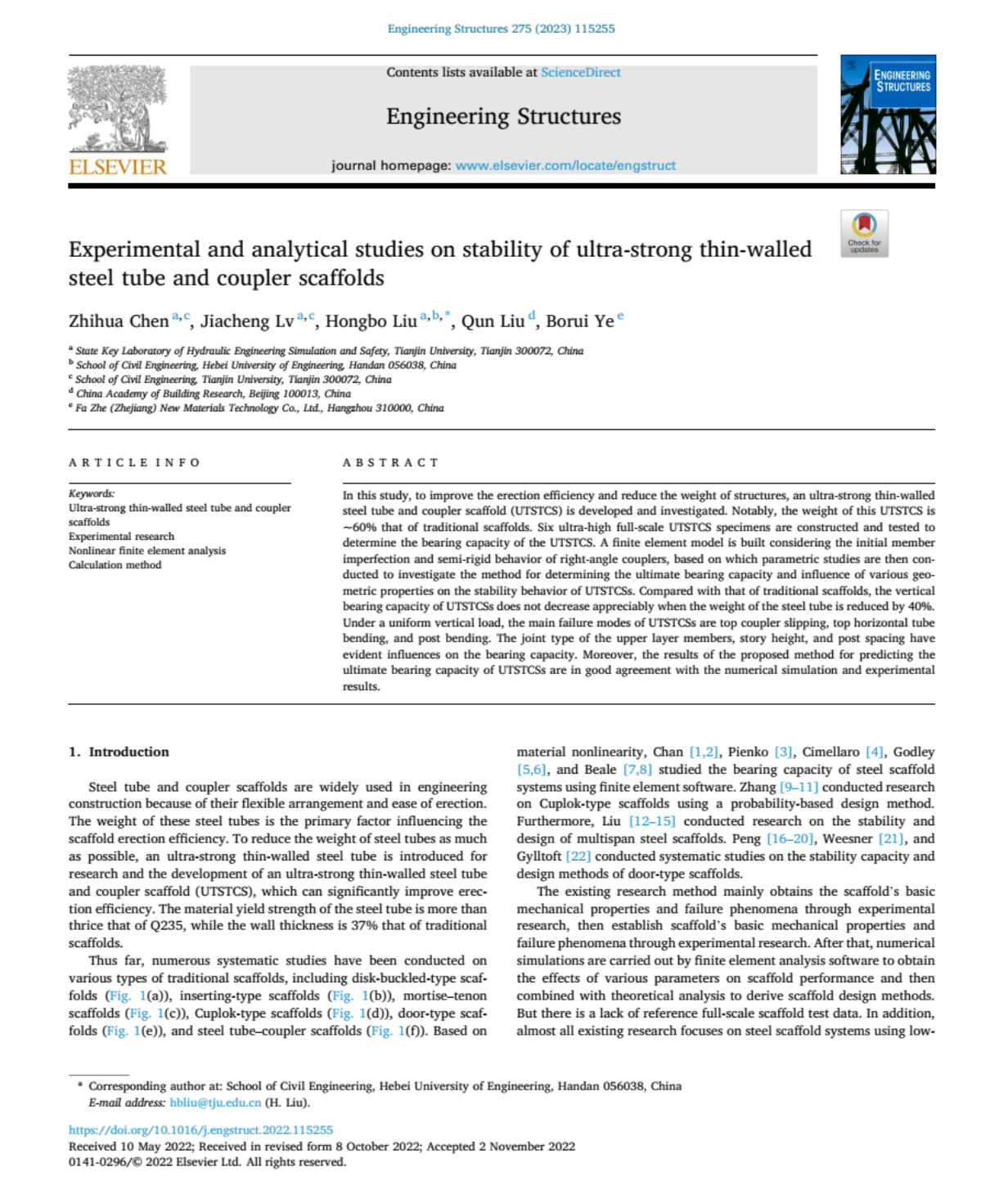

This breakthrough achievement, Experimental and Analytical Studies on Stability of Ultra-strong Thin-Walled Steel Tube and Coupler Scaffolds, has been published in the top-level international journal of structural engineering, and it has been evaluated as "opening up a new paradigm for the stability research of high-strength thin-walled temporary structures."

The national first-class novelty retrieval report (No.:202333B2100441) issued by Zhejiang Institute of Science and Technology Information confirms: "The related technologies have not been reported in the world."

Third, scientific verification: 12 groups of full-scale experiments establish the most stringent database in the world.

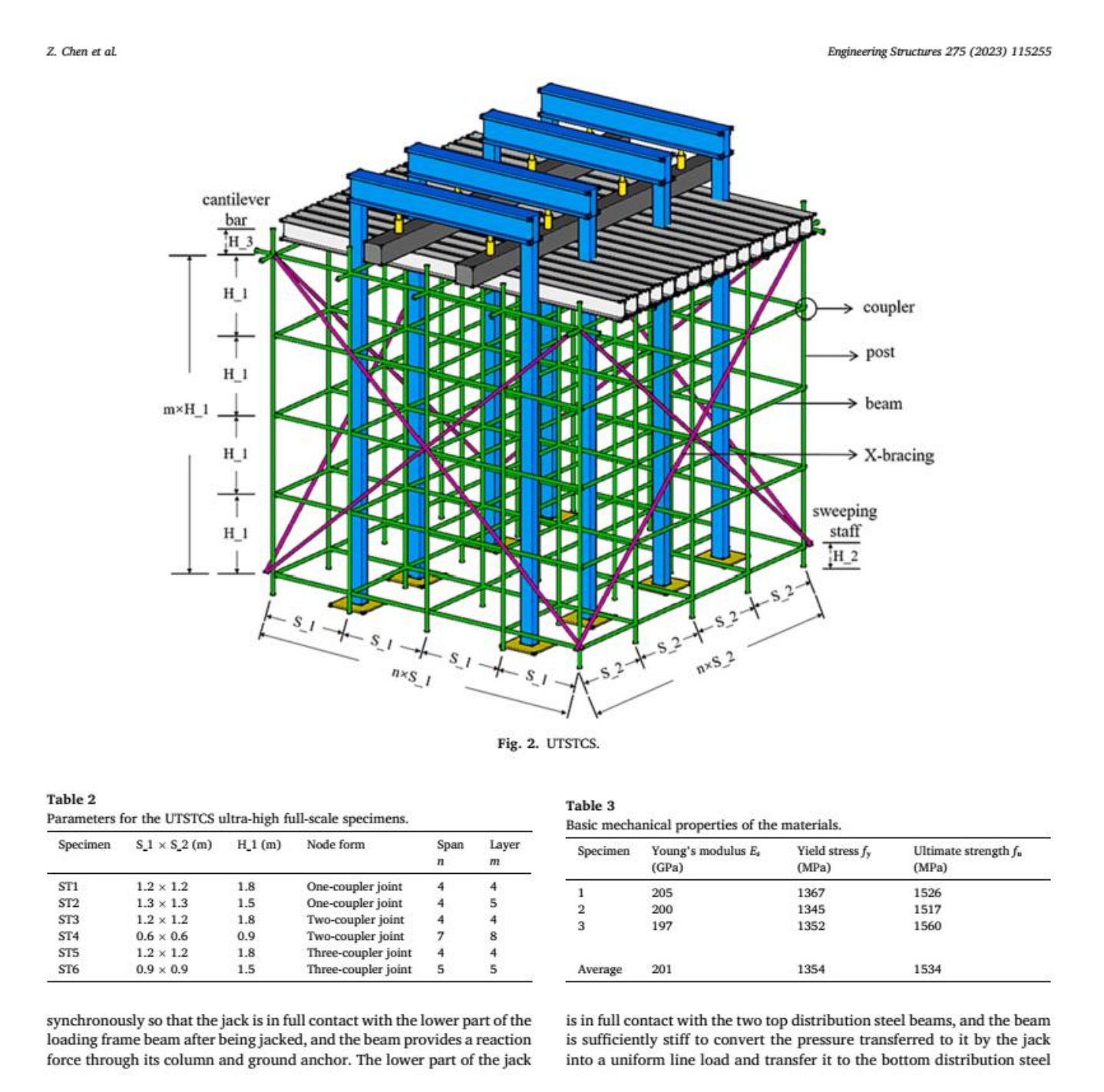

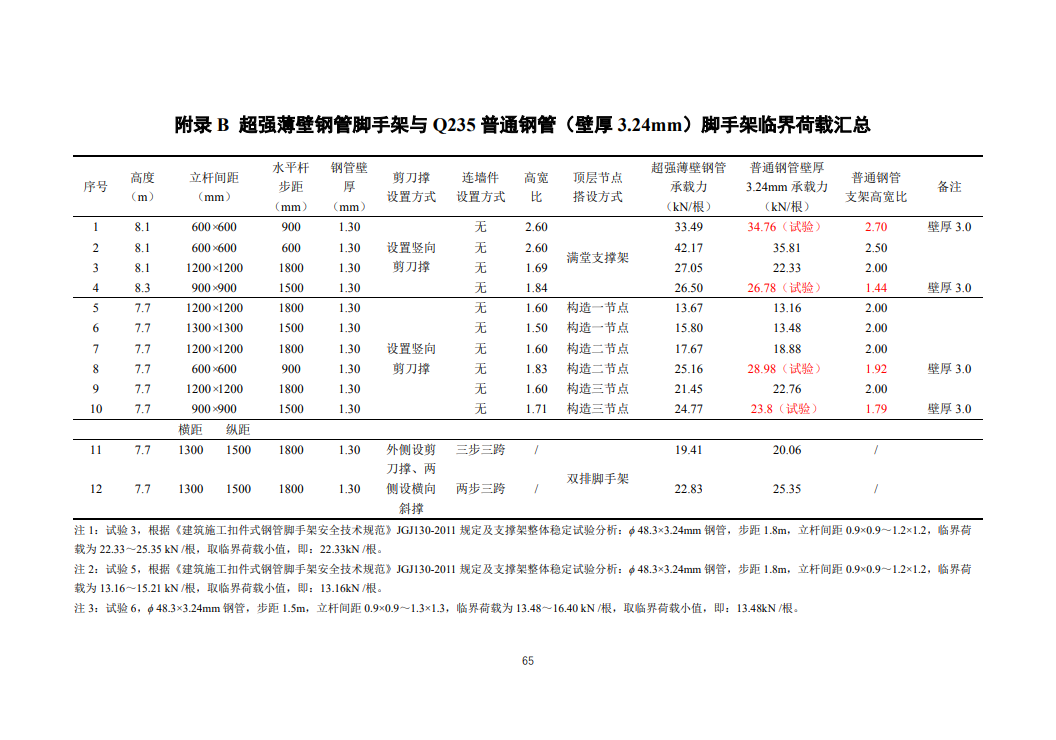

In the Structural Laboratory of Tianjin University, the joint team completed 12 groups of full-scale full-scale scaffolding destructive tests, covering typical working conditions such as full-house support and double-row scaffolding. In the experiment, China Construction Technology Group provided the engineering boundary conditions, Fazhe (Zhejiang) new material provided the HF1350 steel pipe, Tianjin University broke through the basic theory and loading monitoring, and China Institute of Architecture and Research conducted numerical verification.

The results show that the failure mode of the frame is controllable (top slip → local bulging → overall buckling); The horizontal displacement of the 48-meter elevated body is only 60% of the code limit; The bearing capacity of a single vertical pole reaches 13.67-42.17kN, and the safety reserve is sufficient; There is no risk of sudden collapse, and its intrinsic safety is better than that of traditional thick-walled pipe. In 2023, this achievement won the first prize of "Science and Technology Award" of Tianjin Steel Structure Society.

Fourth, standard guidance: T/CECS 1560-2024 became the world's first high-strength thin-walled scaffold specification.

In 2024, "T/CECS 1560-2024 Technical Specification for Super-thin-walled Welded Steel Pipe Scaffolding" was officially implemented, which was compiled by China Construction Technology Group and China Institute of Construction and Research, and became the first systematic standard covering the design, construction and acceptance of high-strength thin-walled scaffolding in the world, filling the international gap.

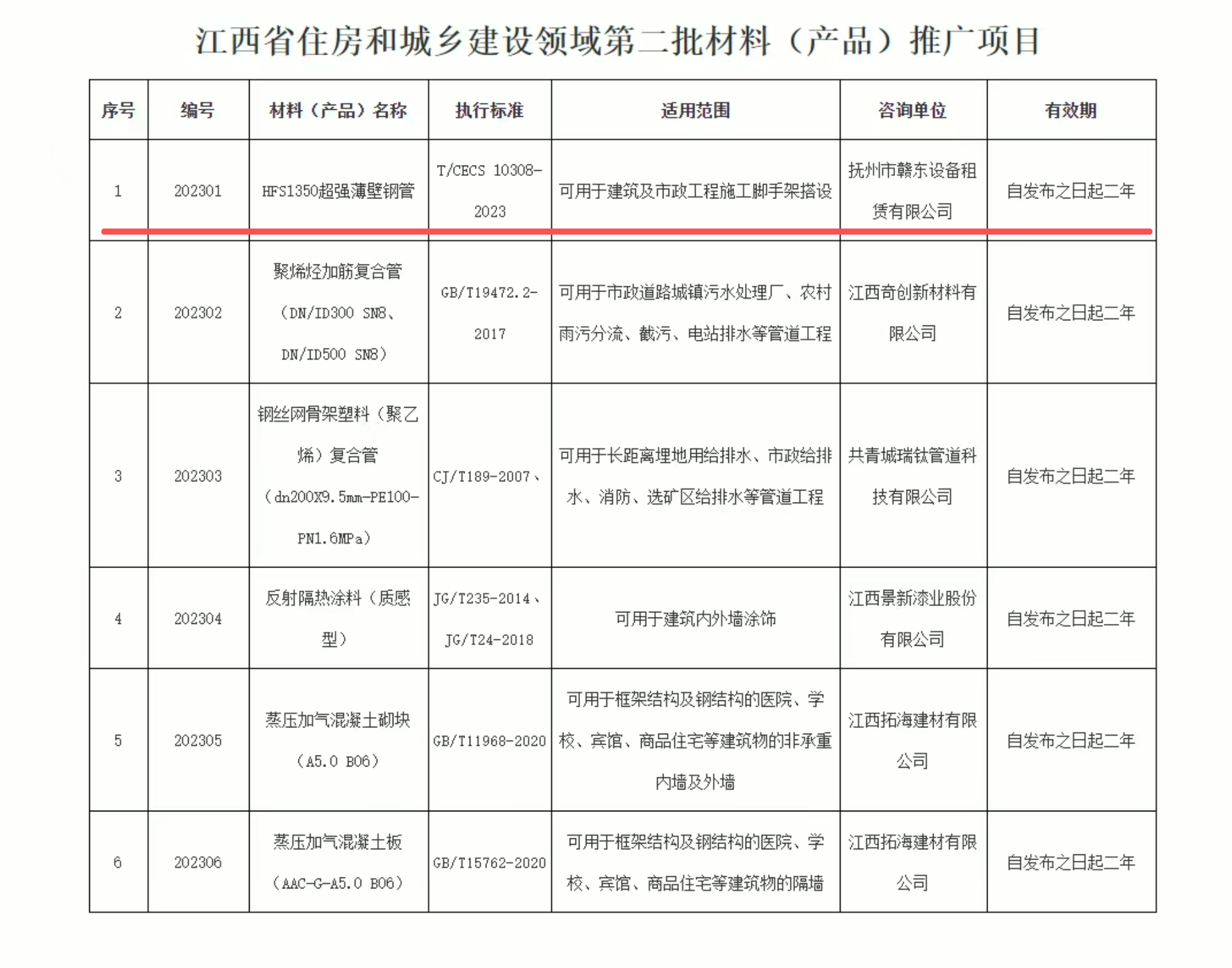

T/CECS 10308-2023 (Material Standard) issued in the same period clearly requires: yield strength ≥1100MPa, tensile strength ≥1350MPa, and zinc layer+corrosion resistant composite coating to ensure durability.

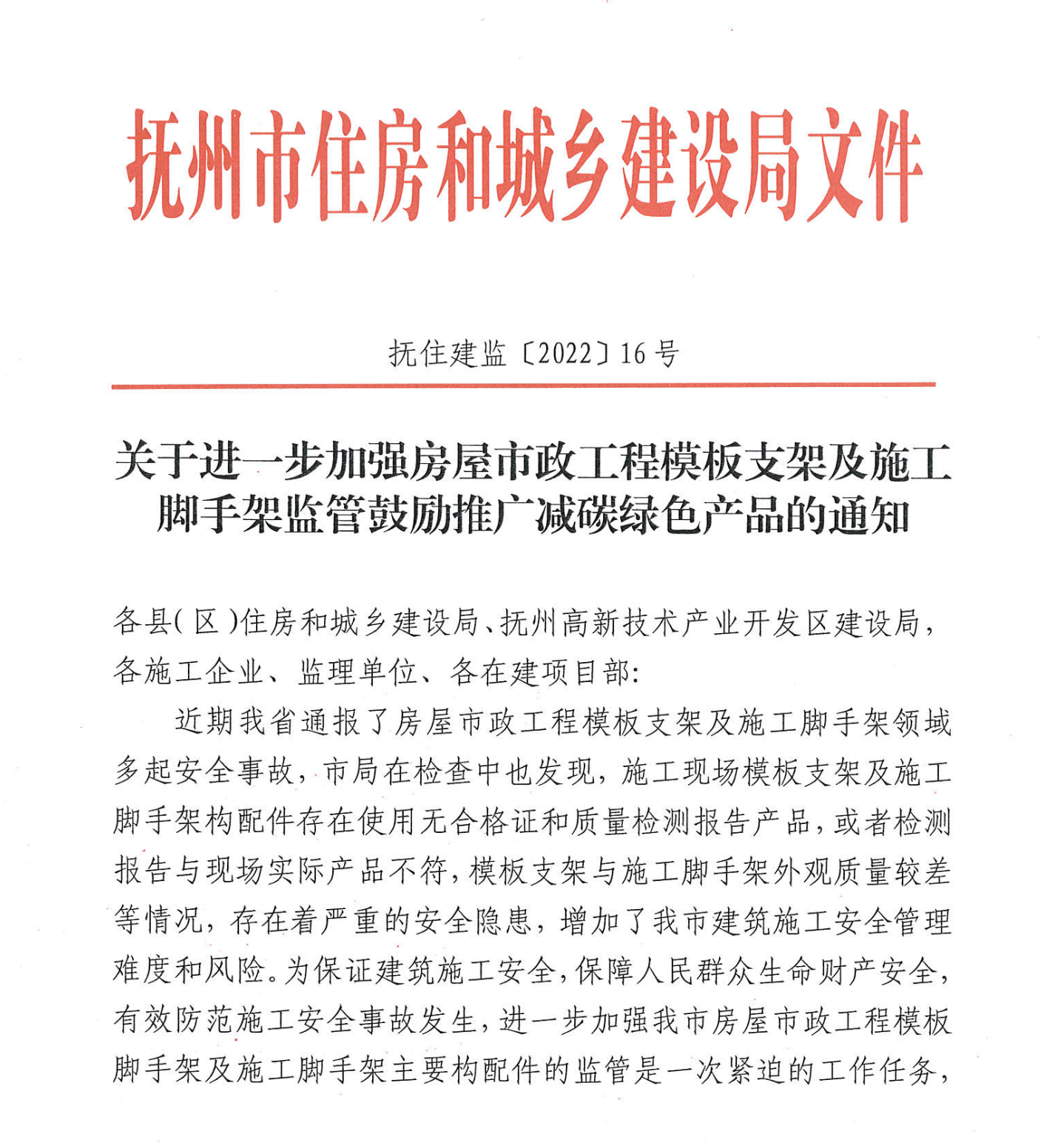

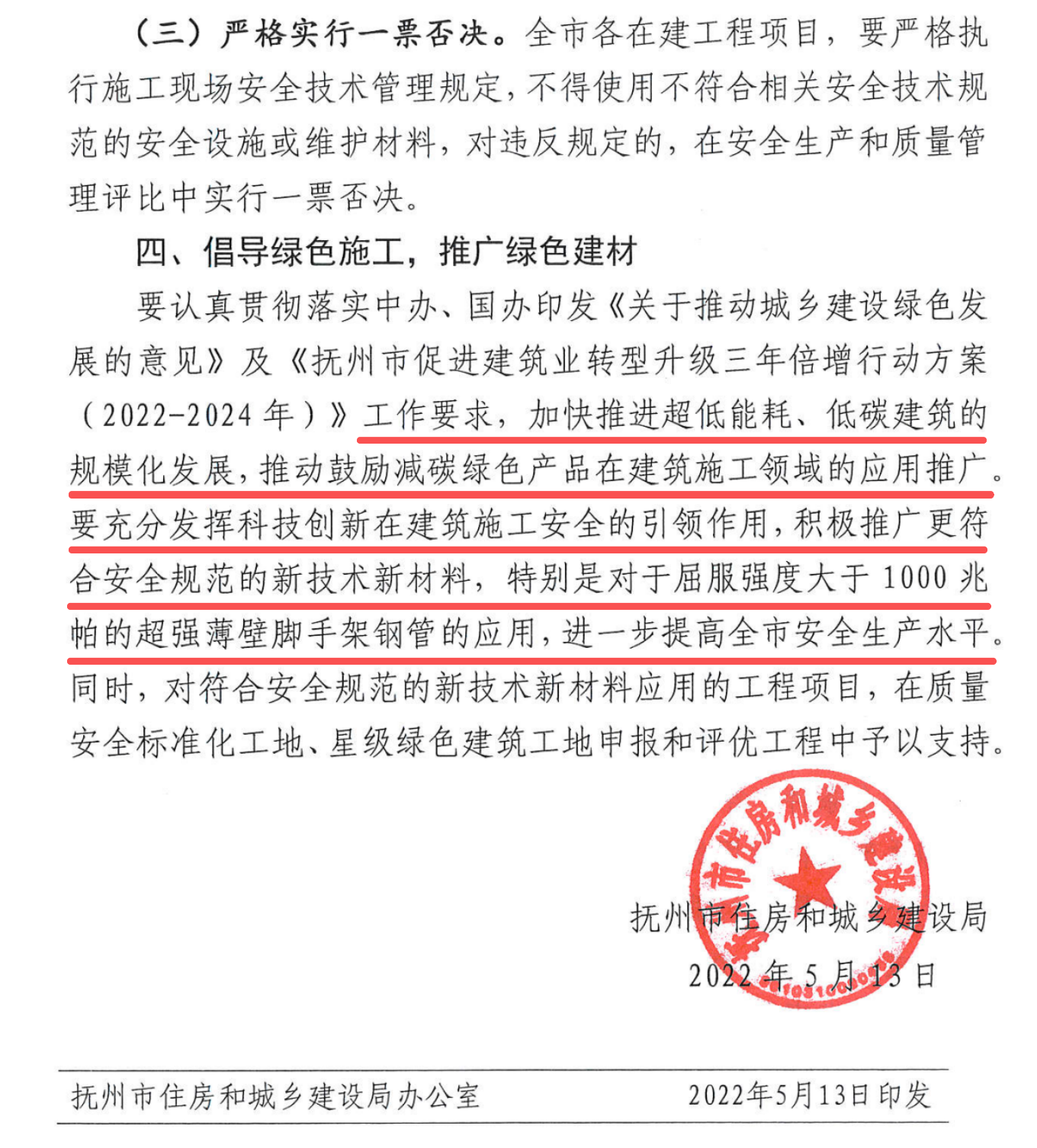

V. Policy coordination: from Fuzhou breaking the ice to Jiangxi province promotion.

In 2022, the article Fu Zhu Jian [2022] No.16 by the Housing and Construction Bureau of Fuzhou City, Jiangxi Province first mentioned "Super thin-walled steel pipe scaffold with yield strength > >1000MPa" and included it in the green site evaluation incentive; On December 15th, 2023, the Housing and Construction Department of Jiangxi Province listed it in the Second Batch of Materials Promotion Catalogue (No.202301) and granted it legal status. Since 2024, many housing and construction departments have started to carry out pilot projects with reference to T/CECS 1560.

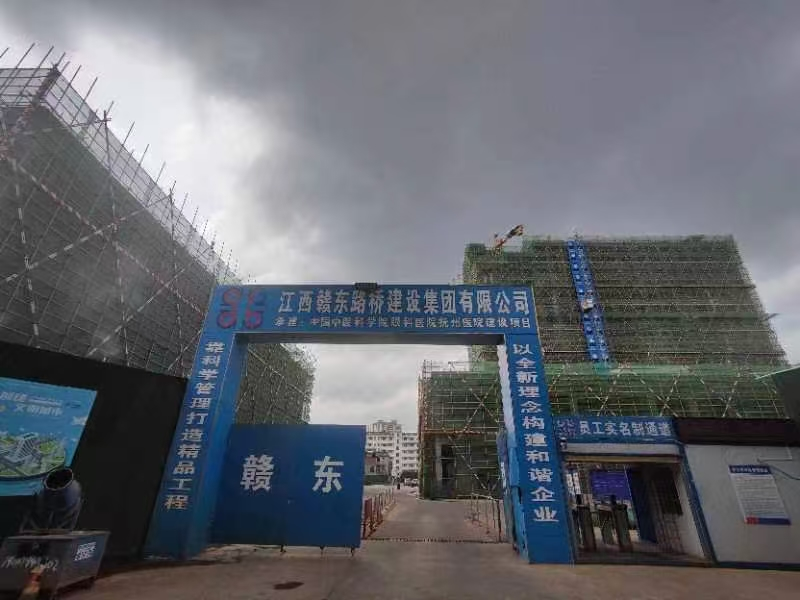

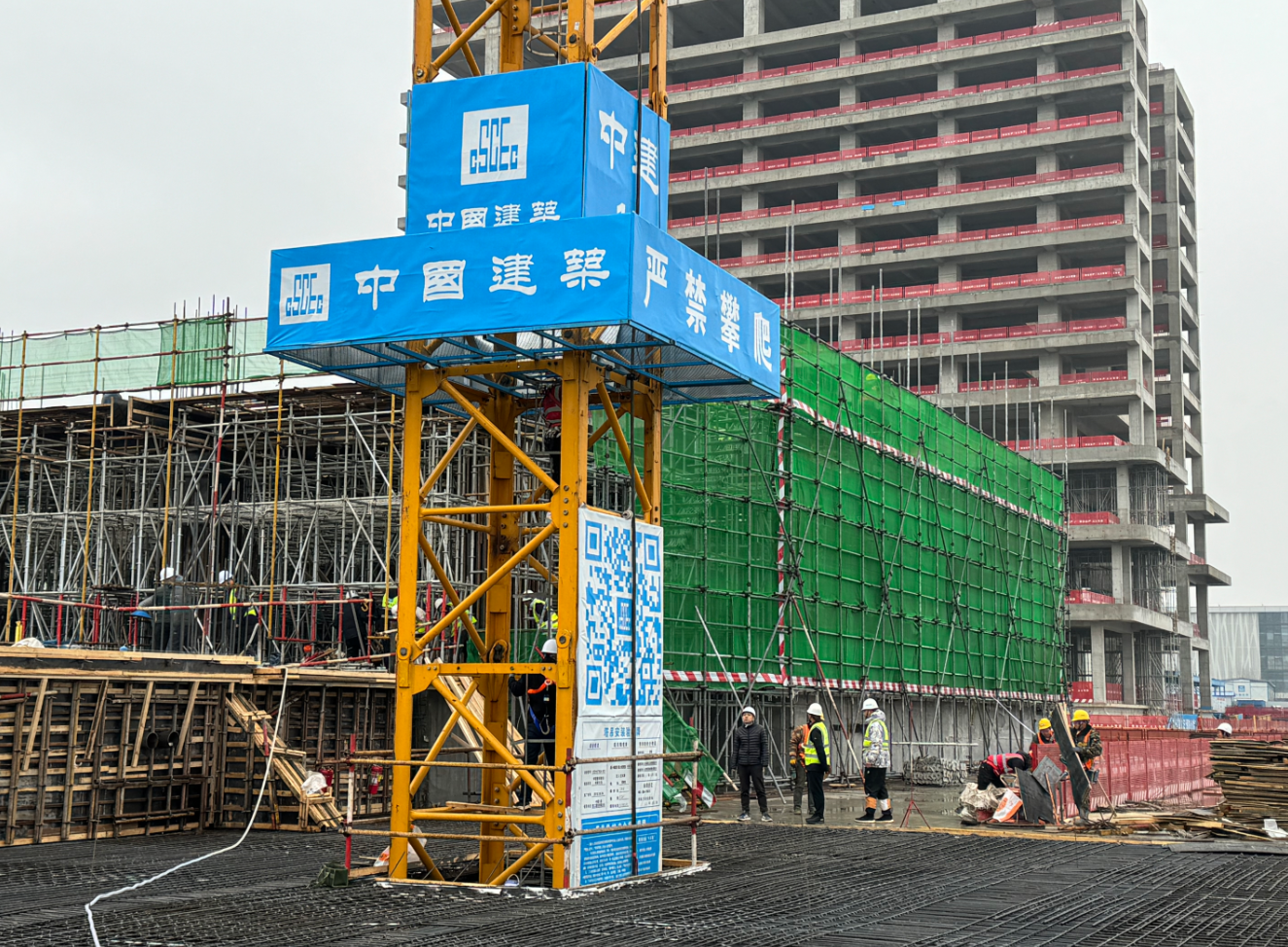

(Fuzhou scale application project)

(https://zjt.jiangxi.gov.cn/jxszfhcxjst/gsgg/pc/content/content_1765289289565532160.html)

6. Project demonstration: Jinan 48m project sets a new benchmark in the industry.

In August, 2024, the project of China Architecture was launched in Licheng District, Jinan. The scaffolding on the facade of a 48-meter high-rise residential building cancels all the cantilever layers of I-beams (the traditional scheme requires two), and after special checking and expert argumentation, the whole height of the scaffold is successfully erected on the ground.

The measured results are remarkable: saving 110 tons of steel and reducing 242 tons of carbon; Save the cost by 270,000 yuan and shorten the construction period by 7 days; Eliminate the common leakage problem of external wall cantilever hole; Zero safety accidents and zero quality complaints.

"In the past, I stopped doing cantilever for 20 meters, and now one is in the end, safe and efficient." The field engineer said with emotion.

(Jinan China Construction Fifth Bureau Cancer Hospital Project)

(48m-high cantilever-free landing scaffold project with single vertical pole in Jinan)

Seven, green value: to provide a quantifiable path for the global construction industry to reduce carbon.

According to the life cycle assessment (LCA), compared with the traditional Q235 pipe, the carbon emission of HF1350 scaffold is reduced by 87% (17,000 tons per 10,000-meter service); Steel consumption decreased by 62%; The design life is 30 years (traditionally about 10 years); Compatible with existing fasteners, and workers switch at "zero learning cost".

If it is promoted by 50% in the global facade scaffolding, it can save more than 10 million tons of steel and 22 million tons of carbon annually, which is equivalent to increasing the annual carbon sequestration of 3 million mu of forests.

Eight, a model of new quality productivity: collaborative innovation of central enterprises+universities+private enterprises

This achievement is a vivid practice of developing new quality productivity: central enterprises (China Building Technology Group and China Institute of Construction Research) provide scene traction and standard formulation; University (Tianjin University) breaks through basic theory and experimental verification; Private enterprise (Fazhe Zhejiang) realizes mass production and process innovation of high-strength steel.

"Without this deep collaboration, it is impossible to complete the leap from 0 to 1 and then to N in just a few years." The project leader stressed.

The experimental data of the joint State Key Laboratory of China Academy of Architecture and Tianjin University show that the comprehensive performance of super thin-walled shelf tube with a wall thickness of 1.3mm and a diameter of 48.3mm is better than that of shelf tube with a wall thickness of 3.6mm (actual thickness of 3.25mm) and a diameter of 48.3mm in the traditional national standard.

Conclusion: small steel pipe, big strategy

In this quiet construction revolution, a steel pipe with a diameter of 48 mm and a wall thickness of 1.3 mm is becoming an important carrier for China to export a new construction paradigm with high performance, low consumption and high safety to the world. It not only propped up tall buildings, but also propped up a greener, fairer and more sustainable future for human beings.

Facing the Tenth Five-Year Plan, with the accelerated construction of the green construction system, this kind of original technology from China, which is "small but beautiful, refined but strong, green and practical", will certainly contribute more wisdom and strength to the global sustainable development in the process of Chinese modernization.